| Availability: | |

|---|---|

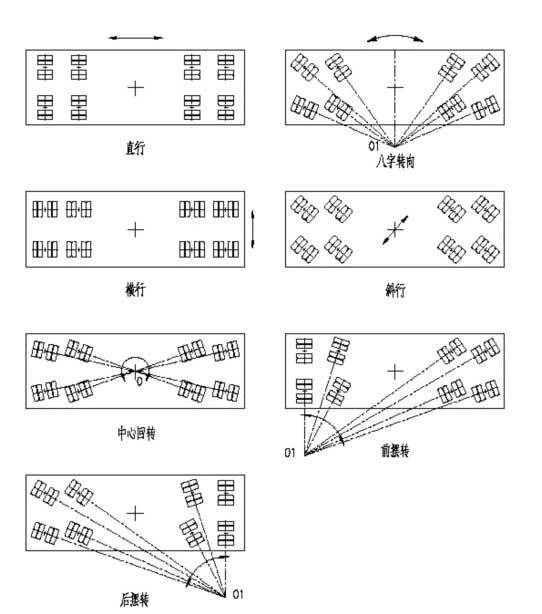

Self-propelled modular trailer using narrow-body module modular design, single module width 2430mm; uniaxial load up to 45 tons, especially for concentrated segment; combination with each module can be achieved up to 1000 axle line module with soft and hard coupling, the maximum load of up to nearly 30,000 tons; with straight, horoscopes, oblique lines, the center rotation, rampant, the former swung, swung, and other post-shift mode, cycling and steering and the same pattern; the product is "national 863 Program "key support for the project, project No. 2009AA044101.

Self-propelled modular trailer is now producing with PPU power pack unit, 4 axle line module, and the 6 axle line module, customers can freely spliced into different combination module as needed.

Production manufacture, use line with national standards, norms, with high rigidity, high shock resistance, high precision; thermal stability; electronic control system with shockproof, anti-magnetic, waterproof, high temperature performance, reliable the completion of ship construction and other construction in the hull section or other heavy goods movement transportation. Simple operation, easy maintenance, attractive appearance. Security guards complete and reliable, perfect automatic protection and alarm functions.

Features

Maximum tractive force for optimum

performance on gradients

– Tractive force 160 kN per axle line

Technical features

– Twin tires 215/75 R 17.5

– Axle load 45 t at 1 km/h

Product Number

PPU L(mm)×W(mm)H(mm) | 4200X2430X1100 |

PPU Lift angle(°) | 11 |

PPU Dead weight (kg) | 7500 |

Engine | DEUTZ |

Engine type | TCD2015 |

Engine Power (kW/ rpm) | 330KW/2100r/min |

Engine fuel consumption(l/h) | 40 |

Engine noise(db) | 85 |

Emissions standards | Euro III |

Fuel tank(l) | 400 |

Hydraulic oil tank(l) | 800 |

Drive system maximum working pressure(bar) | 350 |

Steering system maximum working pressure(bar) | 300 |

Electrical System(V) | 24 |

Product Application

Self-propelled modular trailer is mainly used for shipbuilding, petroleum, chemical, steel and other construction and engineering equipment produced species large or heavy goods transport. Modules can be based on different vehicle's actual condition, select a different combination of modules into a variety of forms to meet the needs of a variety of working conditions. Into the lower bracket module can load, where it will raise the load with top jacking system and transported to any given load down, this process does not require any crane or other lifting equipment. Module driving, lifting, turning to control and drive in the form of a " Mechanical -Hydraulic - Electrical" one. The module is equipped with a remote control and a wireless remote control, its forward or backward with the same efficiency. Two or more PPU can realize stitching, complete control by a person to complete the different transport tasks.

Self-propelled-modular-trailer-goldhofer-pst

self propelled modular trailer spmt

SPMT Self-Propelled Modular Transporter Technical description

SPMT Self-Propelled Modular Transporter adopts narrow body modular design, with single module width of 2430 mm; The single axis axle load can reach 40 tons, especially suitable for concentrated load transportation; With the function of multi vehicle parallel operation, it can realize the soft and hard connection parallel operation of 1000 axis module vehicle at most, and the maximum load capacity can reach nearly 30000 tons; It has many steering modes, such as straight, zigzag, diagonal, center turn, horizontal, front swing, rear swing, etc. the steering modes of single vehicle and parallel vehicle are the same; The product is also a key support project of "National 863 Plan", the project number is 2009aa044101.

The modules produced by SPMT Self-Propelled Modular Transporter

mainly include PPU power module, 4-axis modular car, 6-axis modular car, etc. customers can freely splice into multi axis modular car according to their needs.

SPMT Self-Propelled Modular Transporter is mainly used for shipbuilding, petroleum, chemical, steel and other engineering construction and equipment production, and has been used for medium and large or heavy cargo transportation. According to the actual working conditions, different modules can be combined into various tonnage and forms of transport vehicles to meet the needs of various working conditions. The module car can drive under the bracket of the load, lift the load with its lifting system and transfer it to any designated place to put down the load. This process does not need crane or any other lifting equipment. The driving, jacking and steering of the modular car adopt the control and transmission mode of "mechanical electric hydraulic" integration. The car is equipped with a wireless main remote control and a wireless emergency remote control, which has the same efficiency when driving forward or backward. Two or more power module vehicles can be combined, and one person can control the vehicle completely to complete different transportation tasks.

The manufacture and use of the modular car conform to the relevant national standards and specifications, with high rigidity, high earthquake resistance and high precision; It has good cold and heat stability; The electric control system has the properties of shockproof, antimagnetic, waterproof, high temperature resistance, etc., which can reliably complete the ship building and other engineering construction in the hull section or other heavy goods mobile transportation. Simple operation, convenient maintenance and beautiful appearance. Safety protection device is complete and reliable, with perfect automatic protection and alarm function.

2.1 the altitude shall not exceed 2000m.

2.2 the ambient temperature is within the range of - 20 ℃ - 50 ℃.

2.3 there is no flammable, explosive and corrosive gas in the working environment.

2.4 when working, the wind force is not more than grade 6.

2.5 the pavement used is cement, asphalt and compacted graded crushed stone pavement, no less than grade 3.

3.1 the module car has the function of platform lifting and leveling.

The loading mode of modular vehicle can be freely switched to three-point support state or four point support state; During lifting operation, it can not only lift any single support point, but also lift and lower the whole vehicle.

3.2 the steering system

adopts the hydraulic proportional valve to control the rack cylinder drive mode to make the steering more flexible and stable; The steering adopts micro electric control, which requires shockproof, antimagnetic, moisture-proof and working stability from - 30 ℃ to + 50 ℃.

The vehicle has the following steering modes: straight, diagonal, crosswise, zigzag steering, center turning, swing and so on

3.3 parallel operation function

3.3.1 preset multiple unit module vehicle parallel interface, multiple unit module vehicles can be used by soft and hard connection, that is, multiple module vehicles can be hard connected together through the connecting frame and used as a vehicle; It is also possible to connect all vehicles (with power module) together with parallel cables without any mechanical connection, and use them as one vehicle.

3.3.2 use wireless remote control to control parallel operation; The main remote controller can operate all kinds of vehicles together by pressing the right button.

3.4 drive system

The vehicle is equipped with hydrostatic drive system, which can ensure the flat module vehicle to accelerate and drive smoothly. The speed of the vehicle is stepless and can be adjusted automatically according to the load and throttle.

The drive system has the function of preventing overload and engine flameout. The modular car can automatically prevent the overload of the engine and driving parts, and can obtain

the best torque in any case to avoid the engine flameout.

In addition, the vehicle is equipped with a trailer valve. When there is a problem with the drive system, open the trailer valve and use the trailer to tow the vehicle to the repair site for repair without damaging the hydraulic components.

Mutual rescue function: during parallel operation, when one of the power modules (PPU) loses power (such as engine failure), the hydraulic oil source of the other PPU can be used to drive the powerless module car to realize the slow movement of the train set.

The engine adopts DEUTZ tcd2015 / 330kw / 2100rpm; Turbocharged, electronically controlled engine, Euro III emissions.

3.5 fine adjustment device

The module car is equipped with fine-tuning devices for walking, steering and lifting, which can set the maximum walking, steering and lifting speed of the module car. The walking speed can be controlled in the range of 0-0.1km/h. Under the control of one person, the overall lifting, unilateral lifting and single point lifting and lowering actions of the combined loading platform of each module can be realized, and the multi-mode steering and walking functions of the module car can be cooperated, It can realize the 6-DOF adjustment of the transported goods and facilitate the splicing operation between groups.

3.6 hydraulic suspension

Full hydraulic suspension, can make all axle load evenly; Adjustable platform height, adjustable range ± 350mm, or a group of suspension can be adjusted separately.

The lifting of the platform is controlled by the leveling handle on the remote control. The total lifting stroke of the platform is 700mm. Generally, the platform is lifted 350mm from the lowest position. At this time, the platform is at the median height of 1500mm. The suspension cylinder has enough stroke for axle load compensation. The lifting cylinder is directly installed on the bogie, and the torque is freely suspended, which can avoid the damage of the cylinder.

If special operation is needed, the platform can be tilted and synchronously lifted according to the required angle through the operation of the main controller. In addition, the module car is equipped with four manual hydraulic valves, which can lower the platform to the lowest point in case of emergency.

When the module car runs on the convex concave or inclined road surface, the suspension automatically expands and expands to compensate, so that the load of each suspension is basically equal. No additional jacking tools are required when changing tires.

The suspension cylinder is equipped with explosion-proof valve. When the hose of the suspension cylinder is broken, the oil circuit can be automatically locked to avoid pressure loss of the suspension hydraulic system.

Each suspension cylinder is equipped with two high-pressure ball valves, which can conveniently divide the suspension into three-point support or four point support. The one-way hydraulic lock of German haWe is also installed on each group of supports to further enhance the safety of vehicle operation.

The vehicle is also equipped with an emergency lowering valve. When the power system fails and the goods need to be unloaded immediately, the manual emergency lowering valve can be used to lower the vehicle.

3.7 braking system

The module car adopts hydraulic brake system. It is equipped with service brake. When the equipment is in displacement, it can brake at any time due to the needs of the situation. The brake is reliable, safe, stable and has small impact.

With parking brake, when the vehicle is no longer running for a long time or stops at the parking site, the manual brake is used to park, and the brake wheel set is reliably tightened to ensure that the equipment does not slide.

4.1. Reliability, quality and safety assurance system and measures

Our company has passed ISO9001 certification system, with perfect quality assurance institutions and measures. According to the requirements of flat car on the cleanliness of hydraulic system, the company purchased large hydraulic system washing machine, oil filter car, hydraulic oil particle size detector. In order to ensure the installation reliability of the hydraulic pipeline, the company has also purchased a number of special equipment, such as the pre installation machine for the ferrule joint of Parker company of the United States and the washing machine for the large hydraulic system.

The design, manufacture and acceptance of module car are carried out according to ISO9001 quality assurance system.

The design of the frame adopts the computer finite element calculation method to ensure the safe and reliable bearing. The frame has compact structure, serialization of module specifications and high interchangeability, which can meet different transportation requirements.

The suspension, axle and other bearing parts are mature and general parts which have passed the engineering test, with a high degree of standardization.

Hydraulic system, electrical system selection according to our company's mature program.

SPMT Self-Propelled Modular Transporter adopts electronic control hydrostatic drive system, electronic synchronous control hydraulic lifting system suspension, all wheel independent steering, frame hydraulic leveling and three-point / four-point support technology, which can realize the load function of carpooling, and drive, lifting, steering and other system functions are controlled by micro processing unit connected with CAN bus.

Due to its high mobility, flexible steering, good coordination, and low requirements for the use environment, SPMT Self-Propelled Modular Transporteris especially suitable for the equipment transfer at the engineering site and the long and short distance transportation in sections and large sections. It is widely used in the shipbuilding process and can not be replaced by other means of transportation.

SPMT Self-Propelled Modular Transporter adopts hydrostatic driving system. The driving system includes diesel engine and hydraulic oil pump connected with driving, steering and lifting systems. The adjustable axial piston pump works on the piston motor installed on the driving shaft and has an electronic control system to improve the efficiency and safety of the driving system.

SPMT Self-Propelled Modular Transporter drive system adopts closed loop operation, and its control and regulation functions are the same as those of automatic transmission system, so it is impossible to overload or stops the diesel engine unexpectedly when the vehicle is running. The speed of the diesel engine is adjusted by the acceleration pedal, and the hydraulic oil quantity of the driving pump is automatically adjusted according to the speed of the diesel engine. Accordingly, the gear ratio between the driving pump and different hydraulic motors will also change, thus changing the walking speed.

The SPMT Self-Propelled Modular Transporter is equipped with electronic over-speed safety protection device to prevent the hydraulic motor from over-speed operation and out of gear with other hydraulic motors when the vehicle is running on slippery ground or the driving suspension loses traction. The device can also be used as an independent locking device to prevent the movement of a single driving wheel.

SPMT Self-Propelled Modular Transporter is a new way to transport heavy components. German TII group has set a world record of transporting 15000 tons of oil platform with this device, and the error is only 2 mm. China is in the ascendant in this field.

SPMT Self-Propelled Modular Transporter is generally driven by hydraulic or electric power and can move along more than two axes. Multiple vehicles can be combined to carry larger modules. At first, this kind of vehicle was developed for the aerospace field, and then gradually used in various large-scale engineering construction and shipbuilding industries. SPMT Self-Propelled Modular Transporter was first used in the field of space launch. NASA of the United States began to use German kmag SPMT Self-Propelled Modular Transporter to carry American rockets as early as 1979. China has also used a variety of similar vehicles in the field of space launches. The application of SPMT Self-Propelled Modular Transporter in shipbuilding is a new technology in recent years. The new aircraft carriers of Britain and America both use SPMT Self-Propelled Modular Transporter to carry parts of the aircraft carrier.

Our company has the SPMT Self-Propelled Modular Transporter with the largest load capacity in Asia, and the maximum load mass can reach 2500t. In addition, our company has a variety of spare cars for you to choose from. In addition, our team includes national academicians, design masters, industry professors and senior engineers. For bridge construction, provide services including investment, management, design, consultation, equipment and construction. Bridge construction, bridge rapid installation and disassembly, steel bridge installation and leasing, sales and leasing of bridge erecting machine, beam transporting vehicle and pile pressing vehicle.

SPMT Self-Propelled Modular Transporter It is mainly used in the transportation of heavy, large, high and special-shaped structures. Its main advantages are flexible use, convenient loading and unloading, and the carrying capacity can reach more than 50000 tons in the case of multi vehicle mechanical assembly or free combination. It is widely used in equipment manufacturing industry, petroleum, chemical industry, offshore oil, bridge construction and other engineering fields.

SPMT Self-Propelled Modular Transporter is also known as SPMTs It has the advantages of heavy, large, high and special structure transportation, flexible use and convenient loading and unloading

China began to study SPMT Self-Propelled Modular Transporter in the 1980s, but in the field of manufacturing and engineering construction, it is still unable to compete with the established companies in Britain, Germany and other countries.

The famous SPMT Self-Propelled Modular Transporter brands in the world mainly include Scheuerle, Goldhofer and COMETTO.

The main engineering construction company in the world is British ale, which has all the design and construction capacity, and also has the largest number of SPMT Self-Propelled Modular Transporter in the world. Other international super large cargo transportation companies are mammeet (Holland), sarens (Belgium).

The speed of SPMT is 1-5km / h and the axle load is 30-50t.

how to choose self-propelled modular transporter manufacturers

Different from the large tonnage SPMT Self-Propelled Modular Transporter launched by many manufacturers, the latest customized spmt600 launched by Enerpac is a light SPMT Self-Propelled Modular Transporter with 3 axes for each module. Each module carries 60 tons (20 tons of axle load). It is easy to operate and the operator can master the use method in one day.

TII group is a diversified development direction. Its new products include SL model's transverse splicing 3-column model, AC model's model that can adapt to the polar temperature environment, ES model's large tonnage model with a load of 60 tons per axis, f model's high-speed model with a driving speed of 22 kilometers per hour, and the electric driven SPMT self-propelled hydraulic combined Trailer with good operation performance.

Scheuerle has also done a lot of work on the handling of the vehicle. At the same time, they also provide products under all road, different weather conditions and specific transportation conditions. They believe that the diversity of products is the key factor for their future success in the market competition. Recently, ale and Scheuerle signed a 240 axis order, which shows their leading position in their respective industries.

At present, each manufacturer has its own large tonnage SPMT Self-Propelled Modular Transporter, and the loading capacity of 60 tons per axis is the highest SPMT Self-Propelled Modular Transporter in the world. At the same time, the 60 ton power module also has higher bending moment, which enables it to undertake the transportation of larger tonnage goods. As high tonnage SPMT Self-Propelled Modular Transporter has the same high requirements for pavement, the 60 ton SPMT Self-Propelled Modular Transporter purchased by ale is mainly used in developed countries such as the UK and the Netherlands. Scheuerle said that it was its catering to ale's demand for high tonnage SPMT Self-Propelled Modular Transporter that led to the large order of 240 axis.

Mammoet also purchased many SPMT Self-Propelled Modular Transporter in Scheuerle, including AC series SPMT Self-Propelled Modular Transporter which can operate normally under polar conditions. This kind of SPMT Self-Propelled Modular Transporter is equipped with hybrid rubber sealing ring which can adapt to low temperature environment, auxiliary power station for engine to maintain temperature, and hydraulic oil antifreeze to ensure its normal flow in low temperature environment. Because the polar environment usually requires long-time lighting, its lighting lamps are also replaced by LED energy-saving lamps.

In the aspect of engineering logistics, the general trend is that the size of goods is getting bigger and bigger, the weight is getting heavier and heavier, the size of modules is getting bigger and bigger, and the center of gravity is getting higher and higher, so a wider SPMT Self-Propelled Modular Transporter is needed to carry the modules with high center of gravity. So Scheuerle developed SL model to make SPMT Self-Propelled Modular Transporter horizontal to increase width.

(also known as SMPT). It is mainly used for the transportation of heavy, large, high and special-shaped structures. Its main advantages are flexible use, convenient loading and unloading, and its carrying capacity can reach more than 50000 tons in the case of multi vehicle mechanical assembly or free combination. It is widely used in equipment manufacturing industry, petroleum, chemical industry, offshore oil, bridge construction and other engineering fields.

Product Design protection

Reliability, quality and safety assurance system and measures

Our company has passed ISO9001 certification system, with perfect quality assurance mechanism and measures. For flatbed truck hydraulic system cleanliness requirements, the company purchased a large washing machine hydraulic systems, oil filter car, hydraulic oil particle detector. To ensure the reliability of the hydraulic piping installation, the company also purchased the company's US PARKER fittings preinstalled machines, washing machines and other large hydraulic systems a number of special equipment.

Module vehicle design, manufacturing and inspection according to ISO9001 quality assurance system.

Frame design using computer finite element method, to ensure safe and reliable hosting. Compact frame design structure, module specifications series, high-performance swap meet different transport requirements.

Suspension, axles and other components made through engineering test bearing mature common parts, a high degree of standardization.

Hydraulic system, electric system selection according to the company mature programs considered.