Author: rui trailer Publish Time: 02-19-2024 Origin: Site

SPMT – stand for the strongest vehicle of transport by land

Introduction to SPMT meaning

SPMT

self propelled modular trailer

SPMT also name: self propelled mobile transporter, also known as self propelled modular trailer. Self propelled modular transporter is mainly used in the transportation of heavy, large, high, and special-shaped structures, and self propelled trailer advantages are mainly flexible use, convenient loading and unloading, and the load capacity can reach more than 50,000 tons in the case of multi-vehicle mechanical assembly or free combination. Self-propelled modular transporter is widely used in equipment manufacturing, petroleum, chemical, offshore oil, bridge construction and other engineering fields. In the construction of large-scale projects, off-site prefabricated engineering components are often transported to the site for final assembly, so as to effectively shorten the construction period and reduce the construction cost; If the module is split too much, although it is conducive to transportation and hoisting, but spmt is not conducive to final assembly and commissioning, and the module is split as little as possible, the single module will be very huge, but it poses a challenge to transportation and hoisting, SPMT is born under this demand.The first true SPMT was built in 1983 by Scheuerle and delivered to MAMMOET the following year. 30 YEARS HAVE NOT LEFT THEM OLD, AND TODAY THE FIRST SPMTS IN SERVICE ARE STILL FIGHTING WITH MAMMOET. SPMT has made great progress since its birth, and the world's well-known SPMT brands include Scheuerle transporter (Germany), KAMAG (Germany), NICOLAS (France), Goldhofer (Germany), Cometto (Italy), etc., most of which are European brands (the first three belong to TII Group) As a pioneer, Scheuerle SPMT are used all over the world, with a total use of more than 5,500 axes, and are widely used in shipbuilding, petrochemical, nuclear power, aerospace, road and bridge engineering and other fields. Now in the fourth generation, thanks to the use of welding robot technology, the load capacity of SPMT per axis has been increased from 40t to 48t in the third generation, and the control technology has also reached a new level.

SPMT system composition

01 SPMT module

SPMT modules are available in 2, 3, 4 and 6 axes, with 4 and 6 axes being the most common. With a width of 2.43 m and a length of 5.6 m (4-axis module) and 8.4 m (6-axis module), the SPMT is fully capable of transshipment in standard 20′ and 40′ frame containers. Some super-large engineering companies, the business scope is global, but may not have a local branch, which needs to transport the heavy equipment required for the project to the local area, the transnational transshipment of heavy equipment is generally ocean transportation and land transportation (road and railway) combined, the containerization of equipment can bring great convenience and save a lot of transportation costs, so as to achieve global rapid scheduling and deployment, which is one of the original design goals of SPMT. Each axis is composed of 2 pendulum axles, each pendulum axle is equipped with 2 wheels (pneumatic tires or solid tires are optional), and the central axis of the two wheels can swing at an angle along the center in the vertical plane, which can make the module compensate for the height of the ground in the transverse direction. The module is controlled by a hydraulic system, with a normal height of 1.5 m and a lifting range of 350 mm up and down. Each pendulum axle has an independent hydraulic suspension, but the hydraulic jacks of several adjacent axles are connected in series into several groups of closed circuits, when passing through the ramp or uneven road surface, the hydraulic jack height of each axle can be automatically adjusted by using the circuit cylinder pressure balance to adapt to the ground, and the compensation is made in the longitudinal direction, which is combined with the transverse compensation of the pendulum axle, the load balance of each wheel can be effectively adjusted, and individual tires can be avoided from overloading and puncture. It can also be lifted by manually controlling the hydraulic system to facilitate loading and unloading of goods. When the load is light or unloaded, spmt self propelled modular transporter is even possible to retract some axles without touching the ground to reduce drag loss.The SPMT can be configured with the following 3 types of pendulum axles: Driven pendulum axles – with hydraulic motors, which can draw power from the power unit PPU to drive the SPMT to travel; Brake pendulum axle – non-driven, with compressed air brake; Driven pendulum axle – no drive capacity and braking device, only follow-up

02 Power unit PPU

The PPU (Power Pack Unit) is the power source of SPMT, and it is also an independent module. There are several hoisting holes at the top of it, which is convenient for crane lifting; Turning it over, spmt trailer can be seen that there are 4 universal wheels at the bottom, which is convenient for the PPU to be moved independently. Typically, the PPU is attached to the front of the SPMT module, with two connectors on the upper edge with hydraulics, which can be telescopic to lift the PPU up to 11° and prevent the PPU from touching the ground when the SPMT is going uphill. The model cleverly uses the rotation of the screw to simulate the expansion and contraction of the hydraulic device, and the PPU adjustment elevation angle is also perfectly expressed on the model. In practice, the PPU can also be fixed on top of the SPMT module, often to reduce the overall length of the SPMT. The core components of the PPU are composed of diesel engine, hydraulic pump, control panel, etc., and the connection between the PPU and the SPMT module also includes the docking of hydraulic oil pipes, compressed air pipes, control lines, etc. The diesel engine drives the hydraulic pump, which transmits the hydraulic power through the oil line to the hydraulic motor that drives the pendulum axle in the SPMT module, thus driving the SPMT to operate. A PPU is not necessarily used to drive only one SPMT module, but can also drive multiple modules at the same time, and these modules need to be connected to the PPU with hydraulic hoses, etc.

03 Control technology

The large number of SPMT modules work together efficiently thanks to Scheuerle's cutting-edge control technology. If the spmt transport are in the range of 600 m × 600 m, the control technology can manage and control all the modules in a unified whole.In the whole system, spmt transportation is selected as the main unit, all other units are connected with the main unit through the data line, receive the command of the main unit from the data line to perform steering, driving, braking and other actions, the computer on the main unit manages all the units in a unified manner, and the operator only needs to hold a portable control panel to remotely control the computer of the main unit can easily manage the entire SPMTs cluster. Users can choose to use a wired or wireless remote-control panel.

04 Steering control

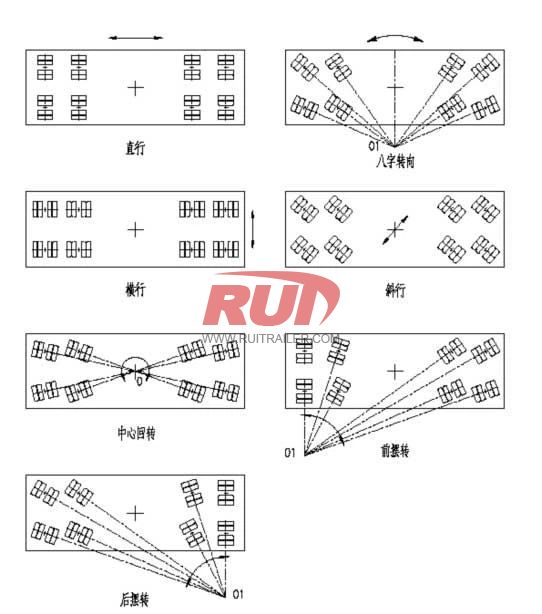

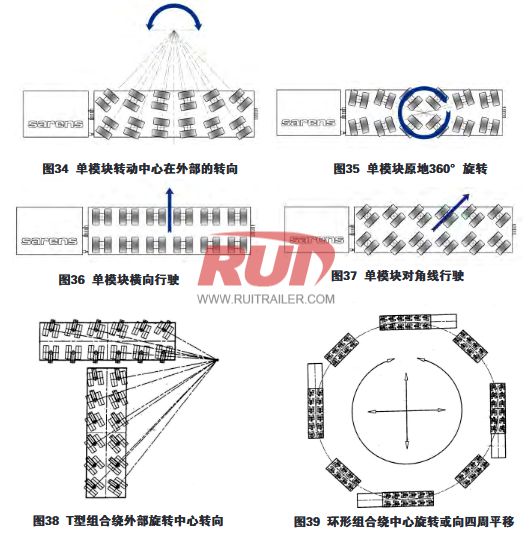

The most intuitive benefit of control technology is the precise and flexible steering control, whether it is the number of modules, or the complexity of the combination, it will not become an obstacle to steering, and the unified management of the computer makes all wheels cooperate seamlessly, and almost any steering action can be made. Several typical steering actions in a single module case are as follows: steering with the center of rotation outside the module; 360° rotation in situ; lateral driving; Drive diagonally. In the case of multi-module combinations, the steering action is equally flexible, e.g. the T-combination is turned around the external center of rotation; The ring combination rotates around the center or pans around.

steering-control-of-SPMT

steering-mode-of-self-propelled-modular-trailer